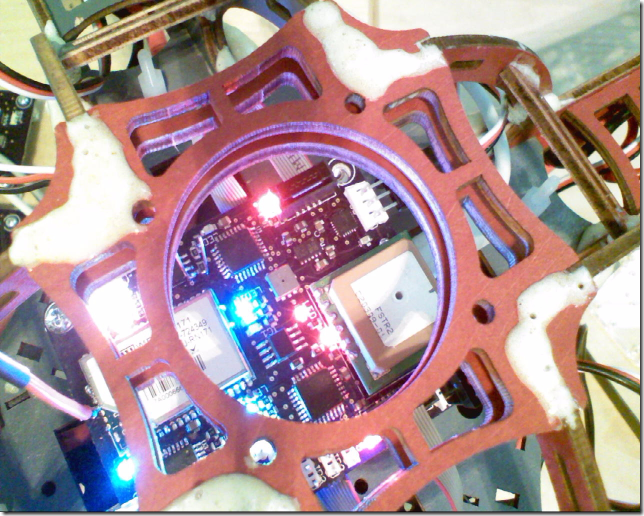

For our April meeting, we will be controlling our Home-Built robot with a Windows Phone device, this should fun so hang on!

We will be using this Bluetooth Module

http://www.amazon.com/Arduino-Wireless-Bluetooth-Transceiver-Module/dp/B0093XAV4U/ref=sr_1_1?ie=UTF8&qid=1395938505&sr=8-1&keywords=Bluetooth+module

And the following USB Serial Port Adapter

http://www.amazon.com/SunFounder-Arduino-Program-Download-Mega2560/dp/B00GD6GE6O/ref=sr_1_10?ie=UTF8&qid=1395938602&sr=8-10&keywords=USB+232

First thing we need to do is configure our BlueTooth Module.

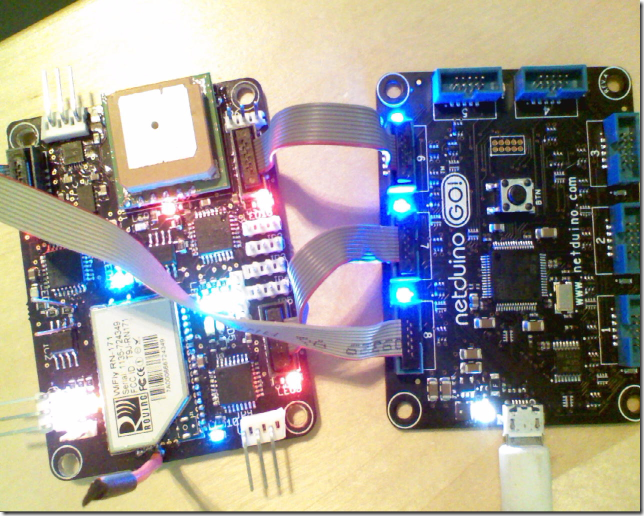

1) Power your Bluetooth Module with your Netduino

VCC –> +5V (Netduino)

GND –> GND (Netduino)

2) Connect your BlueTooth module to your FTDI Serial Adapter

FTDI Netduino BlueTooth Module

GND GND

TX RX

RX TX

3) Open up Device Manager, and identify the serial port that is associated with your FTDI adapter, in my case it’s COM16, yours will probably be something like COM4. A good way to identify your adapter is to unplug, then plug it back in. The one that disappears and reappears is probably the one you want to look at.

3) Download and start RealTerm

4) Configure the initial baud rate of 9600 on the “Port” tab, then press “Change” and “Open”

5) Confirm that your port is open and the correct baud rate is set at the bottom of the screen

6) If all that looks good, then we can start to configure our BlueTooth module, commands need to be sent very quickly. The best way to do this is open up Notepad or some other mechanism where you can enter text and then cut and paste it.

a) Open Notepad

b) Type AT

c) Copy those two characters on to the clip board by highlighting them and hit CTRL-C

b) Right mouse click in the terminal area in RealTerm, and click on “Paste to Port”

c) If all goes well you should see OK

7) Once you know you are connected, enter the text AT+NAMEXXXXXX in notepad, where XXXXX is the name how you want to identify the bluetooth device. No CRLF at the end. Then copy those characters and paste them into RealTerm.

8) Then set the PIN by doing the same thing with AT+PINXXXX where XXXX is the 4 digit PIN used to pair with the device. IMPORTANT NOTE: If you use a PIN code like 1234, or 0000 your phone may try to auto-pair with that value. To get it to work successfully in your app you will need to enter a more non-traditional code, and then manually enter the PIN code via BlueTooth settings.

9) Once you have completed your screen should look very similar to the following. Your settings will automatically be saved to the device and you can continue by connecting it to your Netduino.

Connect the BlueTooth module to Netduino

10) Now you need to connect your BlueTooth module to your Netduino, you can remove the wires from the USB FDTI and connect them to the Netduino. See PDF here for a better view of your Netduino

BlueTooth Module Netduino COM1

RX PIN 1 (TX) - D1

TX PIN 0 (RX) – D0

VCC +5V (from before)

GND GND (from before)

11) Next up is to connect to your BlueTooth device from your Windows Phone 8. You will have to use an actual device, not a simulator. Hopefully you know how to do this, but click on Settings->BlueTooth, make sure it’s turn on, and find the name of your bluetooth module. Make sure you enter a PIN code, if it automatically pairs you may have used a known PIN such as 0000 or 1234, try something different in step #8 above.

12 After you have paired your device, download the following Windows Phone 8 application and make sure you can compile it and run it on your device. Make sure you change the name of the device in MainPage.xaml.cs to match the name of our BlueTooth Device

13) Then download the .cs file that has the code, to insert into your .NET Microframeworks project, the code is very straight forward, just cut and paste the appropriate parts into your application. Also, just populate the code in your project to make the inputs from your phone actually do something.

At this point, your little app should be ready to run!

14) Next download the Windows Phone 8 project.

Enjoy

-twb